Introduction to Safe Chemicals for Dissolving Sludge in Overhead Tanks

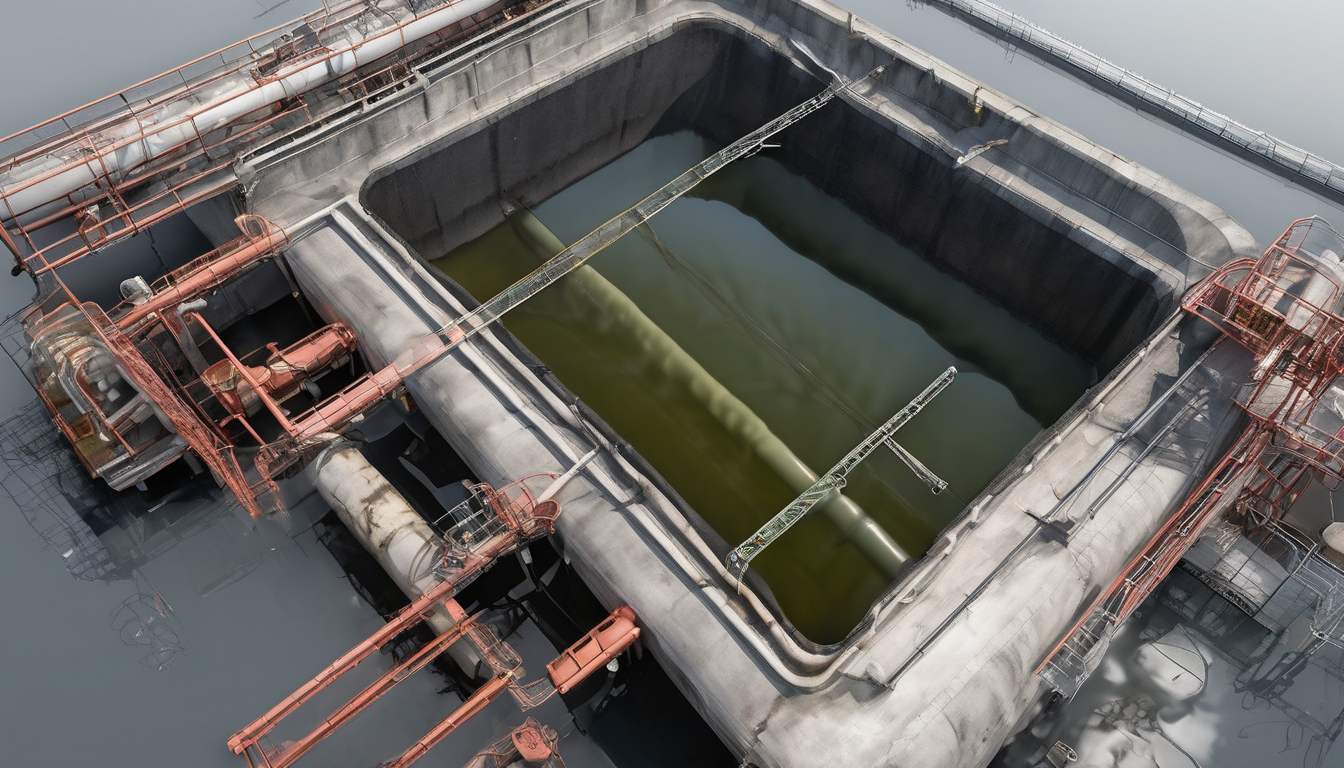

Understanding Safe Chemicals For Dissolving Sludge In Overhead Tanks is essential. Overhead water tanks are an essential part of a building’s plumbing system, ensuring a steady supply of clean drinking water. However, these tanks can accumulate sediment and sludge due to the constant presence of minerals and organic matter. The challenge lies in effectively removing this sludge without introducing harmful chemicals or compromising the integrity of the tank. This article explores safe chemical solutions for dissolving sludge in overhead tanks, ensuring both efficiency and safety.

Understanding Safe Chemicals for Dissolving Sludge in Overhead Tanks

Safe chemicals are essential for the maintenance of overhead water tanks. These solutions not only break down sludge but also ensure that no harmful residues remain, thereby preserving the potability and safety of the stored water. The key to effective chemical selection is understanding the specific needs of your tank system and choosing products approved by local authorities such as Dubai Municipality.

Common Safe Chemicals

- Chlorine-Based Products: These are widely used for disinfection but can also help break down sludge. Products like chlorine bleach or sodium hypochlorite are commonly available and effective when used according to manufacturer guidelines.

- Polyphosphates: These chemical compounds form a protective layer that dissolves sludge and prevents new deposits from forming. They are particularly useful for tanks with severe sediment buildup.

- Acids: Sulfuric acid or citric acid can be used to dissolve hard water scale and rust, making them effective in older tanks where mineral deposits have accumulated over time.

Choosing the Right Chemicals for Your Tank

When selecting chemicals for your overhead tank, it is crucial to consider several factors:

- Type of Sediment: Different chemicals work better on various types of sediment. For instance, polyphosphates are highly effective against organic sludge.

- Tank Material: The type of tank material (steel, concrete, GRP) influences the chemical compatibility and effectiveness. Always refer to manufacturer guidelines for specific recommendations.

- Water Quality: The quality of your water can affect how chemicals interact with sediment. Hard water may require stronger or different chemical formulations.

- Local Regulations: Ensure that any chemical you choose is approved by local health and safety authorities, such as Dubai Municipality’s standards for potable water hygiene.

Preparation and Procedure for Chemical Application

The preparation and application of safe chemicals require careful planning to ensure both effectiveness and safety. Follow these steps:

- Drainage and Isolation: Drain the water from the tank, then isolate it to prevent accidental overflow during cleaning.

- Application Method: Pour the chosen chemical solution directly into the tank according to the manufacturer’s instructions. Ensure that you use the correct dosage for your tank size.

- Mixing and Circulation: Once the chemical is added, circulate the water gently but thoroughly using a pump or by opening faucets in different parts of the building. This helps distribute the chemical evenly throughout the tank.

Post-Treatment Rinsing and Refilling

After applying the chemicals, it is essential to thoroughly rinse out any remaining residue before refilling the tank:

- Rinsing: Open all water outlets in your building to allow the treated water to flow through the system. Continue this process until you see clear, odor-free water exiting the faucets.

- Refilling and Inspection: Once the tank is clean, refill it with fresh water. Perform a final inspection of the water quality to ensure that all contaminants have been removed.

Case Study Example: A Practical Guide

A recent case study involved a large apartment complex in Dubai where tanks were experiencing severe sludge buildup due to high mineral content and infrequent maintenance. The property manager opted for a comprehensive cleaning using a combination of polyphosphates and chlorine-based products.

The process began with thorough preparation, including draining the tank and isolating it from other systems. A 50 ppm solution of sodium hypochlorite was used to disinfect the tank, followed by a 1% polyphosphate solution to dissolve sludge deposits. After an hour of circulation, the tank was rinsed out thoroughly before being refilled with fresh water. This relates directly to Safe Chemicals For Dissolving Sludge In Overhead Tanks.

The results were impressive: the water quality improved significantly, and there were no further issues reported from residents regarding sediment or odor in their taps. This case underscores the importance of regular maintenance and the use of safe chemicals to prevent long-term contamination.

Expert Tips for Effective Cleaning

To achieve optimal results when dissolving sludge in overhead tanks, follow these expert tips:

- Regular Maintenance: Schedule routine cleanings every six months to a year to prevent the accumulation of significant sediment.

- Chemical Rotation: Use different chemical types for periodic cleaning to address various contaminants and ensure long-term effectiveness.

- Proper Ventilation: Ensure good ventilation when handling chemicals to minimize inhalation risks. Always wear appropriate protective gear, such as gloves and a mask.

- Pump Circulation: Utilize pump circulation during the cleaning process to promote better chemical distribution and dissolution of sludge.

FAQ Section: Addressing Common Questions

Here are answers to some frequently asked questions about using safe chemicals for dissolving sludge in overhead tanks:

- Q: Can I use any chemical to clean my tank?

A: No, always choose products approved by local health and safety authorities. Unapproved chemicals can be harmful and violate regulations. - Q: How often should I clean my overhead water tank?

A: It is recommended to schedule a thorough cleaning every six months to a year, depending on the type of sediment buildup in your tank. - Q: What are the risks of using unsafe chemicals?

A: Using unsafe chemicals can lead to water contamination, health issues, and violations of local regulations. It is crucial to use approved products only.

Conclusion: Ensuring Clean and Safe Water Storage

Safe chemicals are a vital tool in maintaining the cleanliness and safety of overhead water tanks. By understanding the specific needs of your tank system, choosing the right chemicals, and following proper application procedures, you can effectively remove sludge without compromising the quality or safety of your stored water. When considering Safe Chemicals For Dissolving Sludge In Overhead Tanks, this becomes clear.

To ensure optimal results, regular maintenance is key. Remember to follow best practices for chemical use and always adhere to local regulations. By doing so, you can provide clean, safe drinking water to residents and visitors alike, promoting health and peace of mind. Understanding Safe Chemicals For Dissolving Sludge In Overhead Tanks is key to success in this area.