Understanding How to prevent Underground Water Tanks from Buckling

Underground water tanks play a vital role in storing potable water. However, over time, they can suffer from structural issues like buckling due to pressure changes and environmental factors. This guide will walk you through the steps to prevent underground water tanks from buckling.

Prevent Underground Water Tanks From Buckling – Identifying the Causes of Underground Tank Buckling

Bucking in underground water tanks is often caused by a combination of factors, including excessive pressure, inadequate design, and poor material selection. Understanding these causes can help you take proactive steps to prevent buckling.

Pressure Issues

When the pressure inside an underground tank exceeds its capacity, it can lead to structural stress and ultimately buckling. This is particularly common in tanks that are improperly sized or those located in areas with high water table levels.

Design and Construction Flaws

Inadequate design and construction methods can also contribute to the risk of buckling. Tanks may be too thin, not anchored properly, or lack necessary support structures such as internal braces and brackets.

Prevent Underground Water Tanks From Buckling – Designing for Resistance Against Buckling

To prevent underground water tanks from buckling, it is crucial to design them with structural integrity in mind. Here are some key considerations:

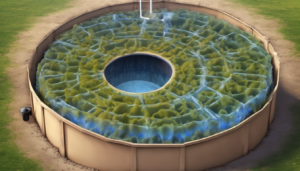

Tank Size and Shape

- Ensure the tank size matches your water needs.

- Select a shape that provides even pressure distribution, such as cylindrical or rectangular tanks.

Material Selection

- Pick durable materials like reinforced concrete or GRP (Glass Reinforced Plastic).

- Consider the weight of the tank and its foundation when selecting material thickness.

Regular Inspections and Maintenance

Regular checks can help identify early signs of buckling before it becomes a serious issue. Here are some inspection points:

Structural Integrity Inspections

- Check for cracks, leaks, or deformations in the tank.

- Evaluate the anchorage and foundation stability.

Pressure Monitoring

- Use pressure gauges to monitor internal water levels and prevent overfilling.

- Ensure safety valves are in place to release excess pressure safely.

Using Appropriate Materials and Construction Methods

The choice of materials and construction techniques significantly impacts the durability of underground water tanks. Here’s what you need to know:

Reinforced Concrete vs GRP

- Reinforced concrete offers robustness but can be heavier and more susceptible to cracking.

- GRP is lighter, more resistant to corrosion, and easier to maintain, making it a popular choice for underground tanks.

Construction Best Practices

- Pour concrete in layers with proper curing time.

- Install internal supports and braces to distribute pressure evenly.

- Ensure the foundation is level and compacted properly.

Implementing Effective Drainage Systems

A well-designed drainage system can prevent water from pooling around or inside the tank, reducing the risk of buckling. Here are some key considerations:

Proper Foundation Drainage

- Install perforated pipes and gravel layers to facilitate water flow.

- Create a sloped foundation with adequate drainage points.

Water-Tight Seals and Joints

- Apply sealants at all joints and connections to prevent leaks.

- Use expansion joints to accommodate movement without compromising the tank’s integrity.

Monitoring Water Quality

Poor water quality can accelerate corrosion and weaken the structural components of your underground water tank. Regularly testing and treating your water can help maintain its clarity and safety:

- Test for pH levels, hardness, and contaminants.

- Treat water with appropriate chemicals to prevent mineral buildup.

- Consider installing a filtration system if necessary.

Expert Tips for Preventing Buckling

Here are some expert tips to ensure your underground water tank remains structurally sound:

- Regular Inspections: Schedule periodic inspections by certified professionals.

- Proper Drainage: Ensure the foundation and drainage system are designed correctly.

- Material Selection: Use high-quality materials suitable for underground applications.

- Maintenance: Regularly clean and maintain the tank to prevent sediment buildup.

Frequently Asked Questions

Got questions? Here are some common queries about preventing underground water tank buckling:

- Q: How often should I inspect my underground water tank?

A: It’s recommended to perform inspections every six months, especially before the rainy season.

- Q: What signs indicate a buckling risk?

A: Look for cracks, deformations, or leaks in the tank walls and foundation.

- Q: Can I prevent buckling with regular cleaning alone?

A: While regular cleaning can help maintain water quality, it’s not enough to prevent structural issues. Structural integrity must also be maintained through proper design and construction.

Conclusion

Preventing underground water tanks from buckling requires a multi-faceted approach that includes careful design, regular maintenance, and professional inspections. By following the guidelines outlined in this comprehensive guide, you can ensure your water tank remains structurally sound and provides safe, clean drinking water for years to come. Understanding Prevent Underground Water Tanks From Buckling is key to success in this area.